Toll Free: 877-355-7577

Phone: 262-785-7577

Fax: 262-785-1066

Email: sales@bct-us.com

![]()

West Allis, WI 53214 USA

Parts and Machinery for the Abrasive Blast Industry

70 Inch Table Blast Machine

Features:

- Unique Roll Up Door

- Lower Operating and maintenance costs

- 10,000 LB Load Capacity

- 2 - 10 HP Direct Drive RimLoc Blast Wheel Assemblies

- Small Operating Footprint

- 3 Phase Operation

- Efficient Design and Operation

- Abrasive Resistant Liners and Cabinet

- Low Noise Level

- Safety Interlocks

- Automatic Timer Controls

- Machine Warranty

- Cartridge Dust Collector

Coyote Centrifugal Blast Wheel

| Wheel: | (2) 3600 RPM, 14" direct drive, bi-directional blast wheels, for maximum abrasive velocity and smooth operation. |

| Blades: | Exclusive Rim-Loc design ensures easy replacement of long life, abrasive resistant, alloy blades |

| Control Cage: | Dial Type Cage |

| Wheel Housing: | Fabricated from 1/4" steel plate and proteccted by replacement cast allow steel liners |

Cabinet Construction

| Cabinet: | Low profile, abrasive resistant steel plate fabrication with fork truck pockets for easy placement. |

| Cabinet Liners: | Interchangeable abrasive resistant liners in all direct blast areas. |

| Work Table: | 70" diameter, 1/2" steel plate construction with completely enclosed heavy duty support bearings, overhead hoist accessible, with standard abrasive resistant liners. |

| Table Drive: | Exterior mounted motor and gear reducer transmit power through a special spring loaded rubber drive wheel. |

| Maximum Area: | 54" at center and 31" at edge |

| Work Load Capacity: | 10,000 pounds maximum |

| Cabinet Door: | Electrically operated, reinforced rubber door provides full access to blast chamber and is positively sealed from abrasive and dust leakage. |

Power and Air Requirements

| Nema: | Type 12 electrical enclosure, optional 230 or 460 volt, 3 phase, thermal overload protection for all motors, Ammeter, oil tight push button controls and digital timer. |

| Air Requirements: | 90-110 PSI required to operate abrasive valve and dust collector automatic blow down. |

| Electric Motors: | All motors are totally enclosed, fan cooled, to provide maximum life. |

| Blast Motor: | (2) 7.5 HP, 3600 RPM |

| Table Drive: | 1/2 HP, 1800 RPM |

| Power Door Motor: | 3/4 HP, 1800 RPM |

| Elevator Drive: | 1.5 HP, 1800 RPM |

| Optional Dust Collector: | 5 HP, 3600 RPM |

Abrasive Recycling System

| Elevator: | Dust-tight, centrifuagl discharge belt and bucket elevator with removalable service and inspection cover, screw adjusted take-up for positive belt adjustment and unique lip separator that filters the abrasive by eliminating light contaminants and unusable abrasive. |

| Abrasive Screening: | Screen in cabinet provides positive blast wheel protection. |

| Abrasive Control: | Totally enclosed, fully adjustable butterfly valve, quietly and precisely controls abrasive flow. |

| Abrasive Required: | 1,000 pounds for initial start-up. |

| Optional: | |

| Attached Dust Collector: | 1200 CFM, self-contained, self-cleaning, 6-cartridge dust collector. |

Safety and Structure

| Safety: | Blast Wheel operates only if door is closed and electrically locked out to prevent accidental opening. |

| Noise Level: | Less than 85 DB |

| Shipping Weight: | 8,000 pounds |

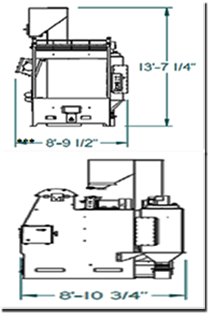

| Machine Dimensions: | 8' 10.75" wide x 8' 9.5" deep x 13' 10.75" tall |

Additional customization is available to fit specific requirements.

In the News

Tumble Blast Machines

1.25 Cubic Ft. Air Blast Machine

1.25 Cubic Ft. Airless Blast Machine

3 Cubic Ft. Air Blast Machine

3 Cubic Ft. Airless Blast Machine

6 Cubic Ft. Air Blast Machine

6 Cubic Ft. Airless Blast Machine

Table Blast Machines

48 Inch Table Blast Machine

70 Inch Table Blast Machine

Model 2460 Spinner Hanger

Model 3072 Spinner Hanger

Other models available.

616 Dust Collectors

632 Dust Collectors

70 Push Table Video

48 Inch Table Blast Video

1.25 Cubic Foot Tumble Blast Video

Pass-Through Blast Video

Spinner Hanger Video

Dimensions