Toll Free: 877-355-7577

Phone: 262-785-7577

Fax: 262-785-1066

Email: sales@bct-us.com

![]()

West Allis, WI 53214 USA

Parts and Machinery for the Abrasive Blast Industry

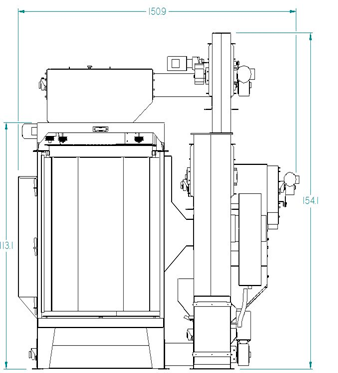

Model 3072 Spinner Hanger

Features:

- Handles Workload Upto 1500 LBS.

- 4 - 15 HP. Coyote Rim-Loc Blast Wheels

- Twin Chamber Blast Cabinet

- Revolving Spindle in Each Chamber

- Spindles Revolve at 11.6 RPM

- ATC Cycle Timer

- Automatic Timer Controls

- 3000 CFM Cartridge Dust Collector Attached

Please call Coyote for information on 3096, 3684, and 4884 Spinner Hangers.

The chambers are indexed by an electric motor and gear reducer activating a low speed-high torque "HTD" type drive assembly.

The spindle automatically engages and disengages as the chambers rotate through the blast zone leaving it free to revolve at the loading zone.Each chamber will stop at a preset index point, set at the top of the cabinet, for a time interval set

on the ATC cycle timer and automatically travel to the next stop until all have been made and then rotate to the end

of the blast zone and wait to be indexed for the next cycle.

The 3072 utilizes (4) 15 HP Coyote Rim-Loc Blast Wheels.

The 3072 utilizes (4) 15 HP Coyote Rim-Loc Blast Wheels.

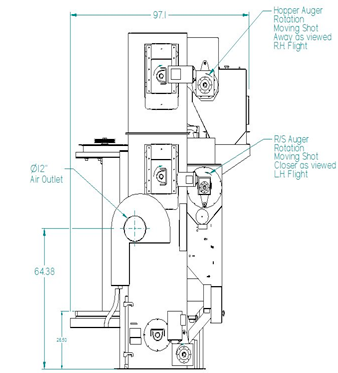

The abrasive is controlled via air-operated butterfly valves. The abrasive proximity, located on top of the main chamber, will signal the abrasive ON when the workload is present in the blast zone and turn OFF the abrasive as the workload passes the zone.

All spent abrasive will drain through the bottom of the chamber and be collected at the lower screw conveyor which will deposit it into the lower elevator where it will be transported to the separator which will remove light contaminant. From there it will travel to the bottom of the upper elevator and then to the storage hopper ready for reuse. The storage hopper has a Polycarbonate window with an adjustable proximity switch that activates

when the abrasive falls below the minimum level. When this occurs, it will illuminate a light on the

electrical panel.

Additional customization is available to fit specific requirements.

In the News

Tumble Blast Machines

1.25 Cubic Ft. Air Blast Machine

1.25 Cubic Ft. Airless Blast Machine

3 Cubic Ft. Air Blast Machine

3 Cubic Ft. Airless Blast Machine

6 Cubic Ft. Air Blast Machine

6 Cubic Ft. Airless Blast Machine

Table Blast Machines

48 Inch Table Blast Machine

70 Inch Table Blast Machine

Model 2460 Spinner Hanger

Model 3072 Spinner Hanger

Other models available.

616 Dust Collectors

632 Dust Collectors

70 Push Table Video

48 Inch Table Blast Video

1.25 Cubic Foot Tumble Blast Video

Pass-Through Blast Video

Spinner Hanger Video